how do rocket engines even-?

it's a pretty hot topic (pun intended) making most of us curious- how they are powered? or even how they are able to withstand such high temperatures and pressure?- explained in layman terms

rocket engines when looked as a whole appear to be a very complex structure and makes one think how can someone even come up with that stuff. Rocket engines are incredible machines with actually a very basic principle

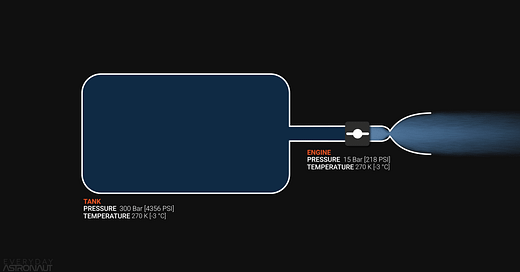

its called newton’s third law of motion “every action in nature has an equal and opposite reaction" (yea just like karma but more science-y). Consider a balloon, when you go of the balloon it throws out gas and moves forward as a reaction, the gas inside the balloon is of high pressure and just like most of us, the gas wants to go from an area of high pressure to an area of low pressure. Now imagine that balloon is made up of a strong metal and boom there you have the Pressure tank. This tank basically stores a propellant (gas) at very high pressure. This was the principle behind the the cold gas thrusters

cold gas thrusters

The simplest form of a rocket engine just stores some sort of propellant in a tank at high pressure. Then, open a valve, and let that high pressure flow out through the engine. This is the basis of cold gas thrusters.

As the name suggests, these engines run cold, meaning that there is no chemical reaction or combustion taking place. The simple expansion of a stored gas through the nozzle is what provides thrust in these types of engines.

biggest con of this system was that the pressure needed to be stored at a very high pressure, to achieve that pressure the walls of the tank needed to be thick to be able to withstand this pressure. This made the system very heavy and you know rocket engineers, they would sign a contract with the devil himself to reduce the overall weight. This led to the making of-

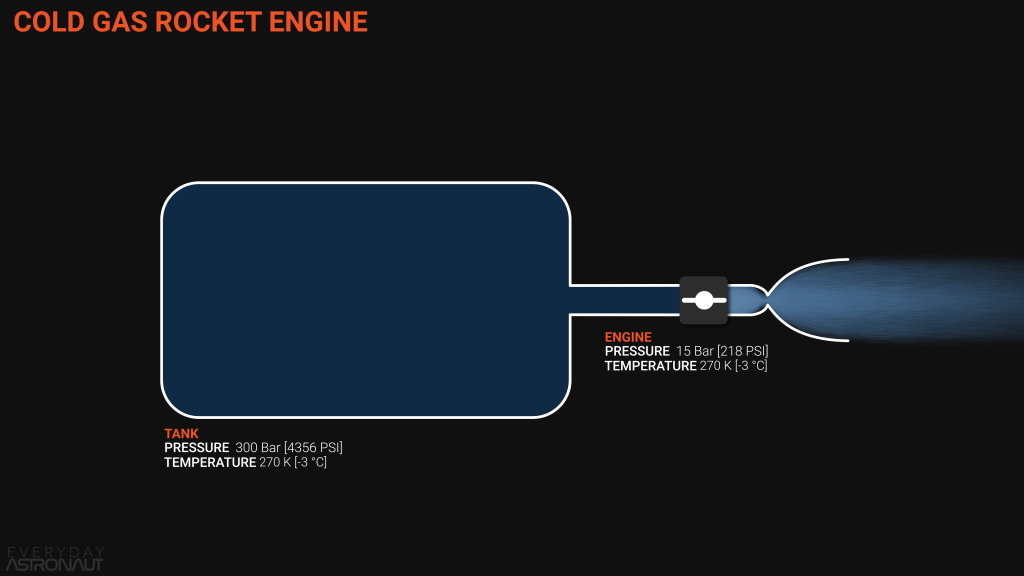

Pressure-Fed Engines

A monopropellant pressure-fed engine, or (for short) monoprop pressure-fed engine, is very similar to a cold gas thruster. The engine still has one tank filled with high-pressure inert gas. However, in addition, there is also a low-pressure tank with propellant which is actually connected to the engine and to a pressure chamber. The pressure inside the chamber is used to flow the propellent from the low pressure chamber to engine

They are a lot efficient than the CGT. Based on this a bipropellant pressure-fed engines were created.

Bipropellant pressure-fed engines, (or for short, biprop) pressure-fed engines, are basically the same as monoprop engines. The difference is, as the name already suggests, a pair of both fuel and pressurant tanks. One set stores the fuel, while the other one stores the oxidizer.

the fuel in one tank reacts with the oxidizer from the second tank at very high pressure in the main combustion chamber. The oxidizer is a source of oxygen that is used for burning of the fuel.

To improve even further we needed to have even higher pressure and increasing it pressure tank wasn’t an option anymore (to maintain the perfect weight). This is where ‘pumps’ come into play. They are attached to the low pressure tanks to increase the pressure without touching the pressure tank.

Pumps require a lot of power to operate like the one’s in RD-170 required about 230,000 horsepower (about 23,000 horses) and to overcome this the idea they came up with is incredible

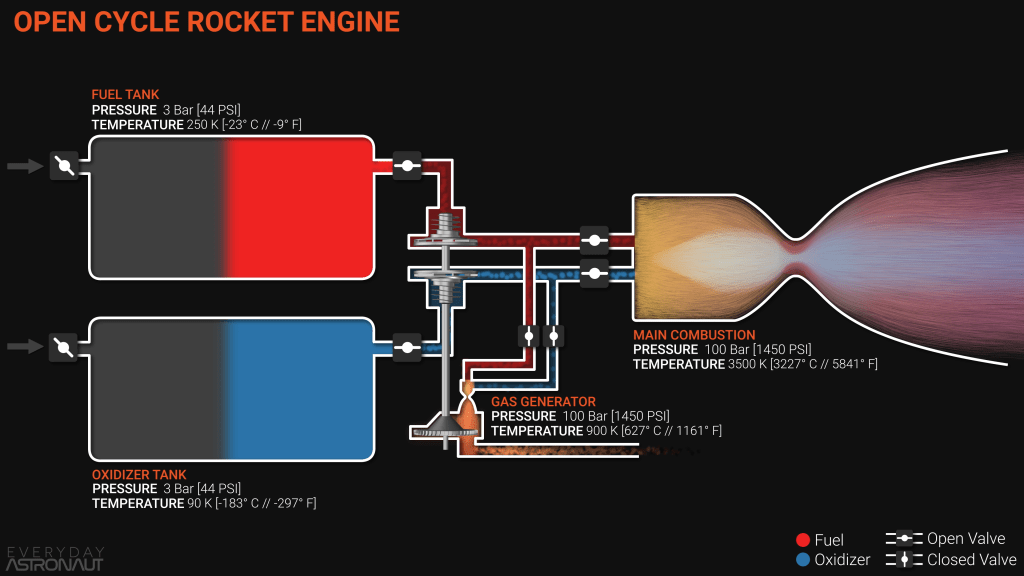

Open Cycle (Gas Generator)

The system looks similar to the biprop but here the main difference is the turbine. The pumps are connected to a single turbine. A small amount of oxidizer and fuel are made to react in a new chamber called gas generator, the gas from here is made to rotate the turbine which in turns makes the pump work

the gas from the turbine is then just thrown out in the form of soot- a black residue left after the burning of the fuel. This soot is not good for the engine, it gets in places and its not supposed to be and makes the machine less efficient

To not let this happen they created a -

Closed (Staged Combustion) Engine Cycle

The closed, or staged-combustion, cycle is a more highly developed approach to try to make use of the combustion products that are dumped overboard on the open cycle.

here instead of the some of fuel and the oxidizer reacting, they either have all of the fuel or the oxidizer passing through the gas generator now called the ‘preburner’. The exhaust pipe is connected back into the combustion chamber. Being either fuel or oxidizer, it has two types-

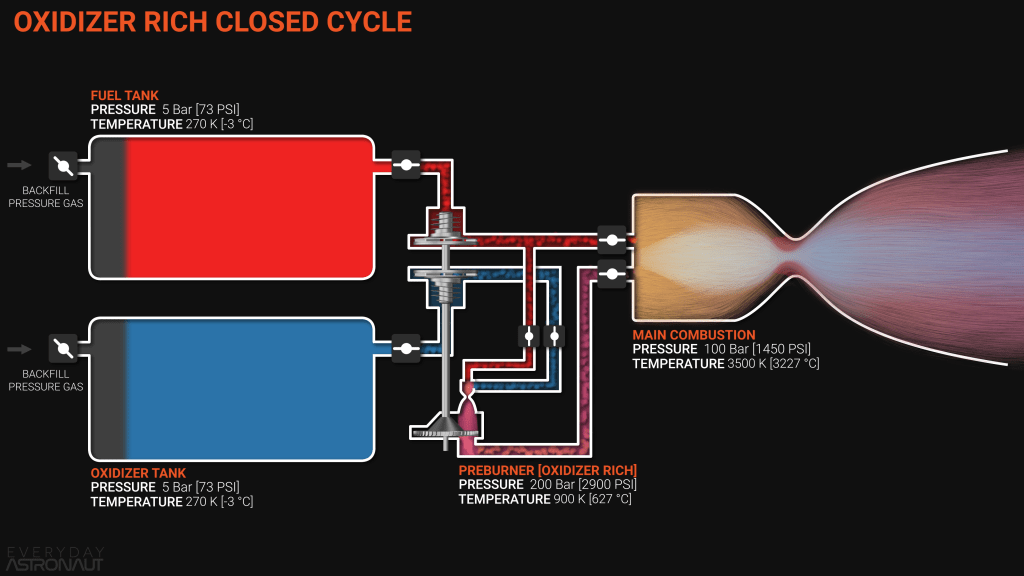

Oxygen-Rich Staged Combustion Engine Cycle

here the whole oxidizer and a part of fuel is made to pass through the turbine and is made to react in the preburner. The oxidizer changes its state from liquid to gas in this process to be able to make the turbine rotate

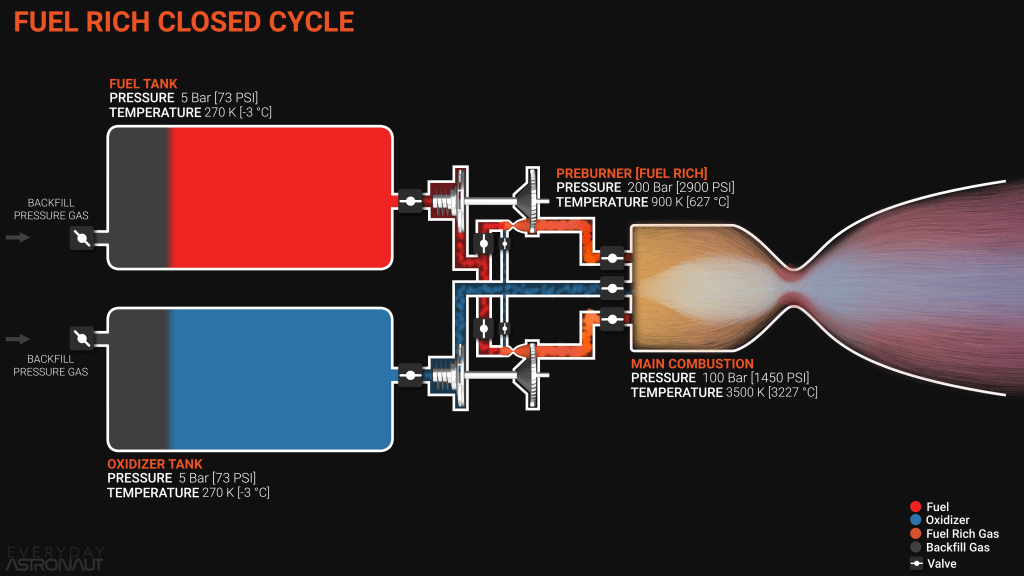

Fuel-Rich Staged Combustion Engine Cycle

the alternative to the oxygen-rich cycle, the fuel-rich cycle. In this case, where in general the relationship between the oxidizer and the fuel is reversed from what we looked at previously. In this case, all of the fuel passes through the preburner, and only a minimal amount of oxygen passes through the preburner.

But we are not stopping here yet, what if I say there is an engine that basically combines every engine mentioned above ?There is one combustion cycle that combines the benefits of both fuel-rich and oxygen-rich cycles, which also combines some of the downsides of each of those – but one specific upside makes it well worth pursuing.

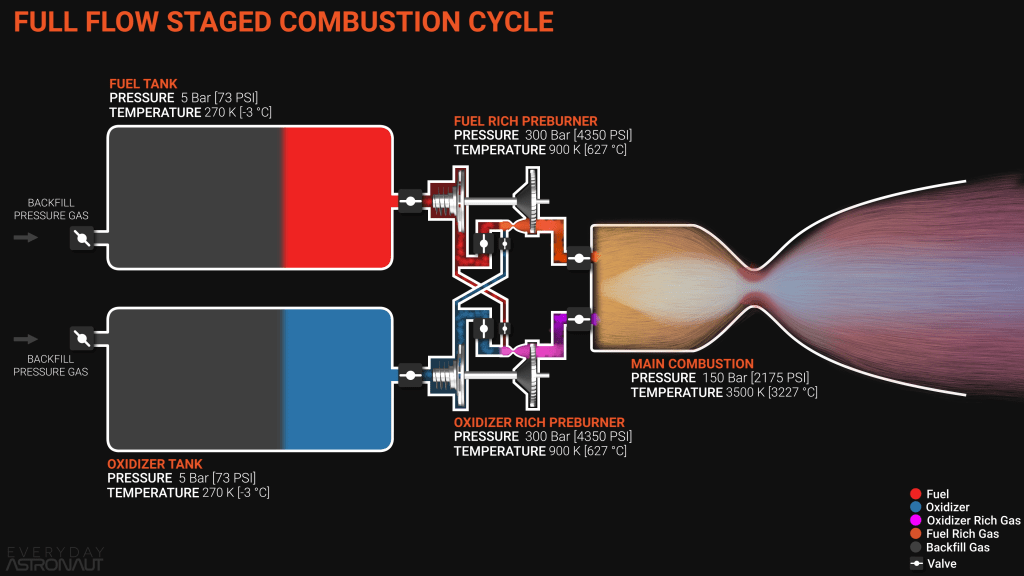

Full-Flow Staged Combustion Engine Cycle

The full-flow staged combustion cycle is named for the flow of the propellants through the preburners. Both the fuel and the oxidizer are totally routed through a preburner and a turbine. This means that the cycle design features both a fuel-rich preburner and an oxidizer-rich preburner.

Almost all of the oxidizer is run through the oxidizer-rich preburner and turbine, with a minimal amount to oxidizer being sent through the fuel-rich preburner. In parallel, almost all of the fuel is run through the fuel-rich preburner and turbine, with a minimal amount of fuel being sent through the oxidizer-rich preburner.

This means that both propellants end up arriving at the combustion chamber already fully in gaseous form. This is a huge advantage over other cycles discussed earlier. A gas-gas interaction is extremely efficient, leads to improved mixing of gas products prior to combustion, leading to faster combustion with less unburnt residuals than liquid-liquid or liquid-gas interactions.

its a fairly new technique and having the pros of both the cycles it also has cons of the both cycles over the problems it has on its own, therefore very few organizations have attempted to manufacture it

There is no best engine, all of the have them have their own pros which help to solve various problems. Looking back its crazy to think that this all made on the basis a one simple principle. Humans kept pushing the boundaries of imagination and science to keep reaching new levels, progressing and making our place among the stars.

if you manage to understand this stuff congrats my friend, cuz its literally rocket science!

stay curious, my friends!!

Sushant Pulipati, your friend at Smort.in